The discovery of Chrome-Moly was a game changer, especially for the high-speed automobile and aircraft industries. But compared to other materials like iron or copper, Chrome-Moly has only been around for a little bit of time. As such, information about Chrome-Moly is riddled with inaccuracies, even in large publications. Here are two of the most commonly reported myths about Chrome-Moly.

First Off, What is Chrome-Moly?

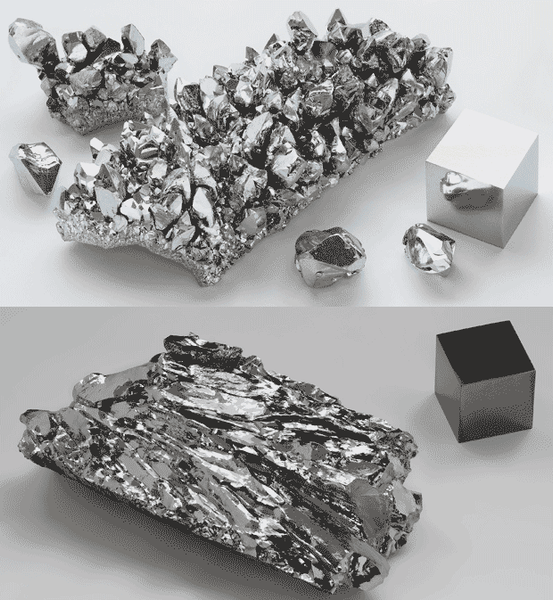

Chrome-moly is an alias. The metal’s real name is actually 41xx Steel. It’s produced from a combination of chromium and molybdenum. While most of us are familiar with chromium, molybdenum is not an element we typically hear about. It’s a type of metal that doesn’t exist in its alloy form naturally and has the sixth highest melting point on the periodical table.

Myth 1: Chrome-Moly is lighter than Steel

Chrome-moly has an excellent weight-to-strength ratio. This makes it ideal for use on any project where weight can be an issue. For instance, chrome-moly is commonly used on motorcycles, higher-end bicycles, racing vehicles and aircraft parts. But if a motorcycle made with chrome-moly weighs less than a motorcycle made with steel, doesn’t that mean that chrome-moly is lighter than steel? No. Practically all high-strength steels have a similar density (specific weight). The reason a motorcycle made with chrome-moly is lighter is because you can use less material to get the same level of strength (since chrome-moly is stronger).

Myth 2: Chrome-Moly must be preheated

There’s still some welding experts that insist on always preheating chrome-moly. They say, “Sure you don’t have to preheat chrome-moly all the time, but it doesn’t hurt to do it anyways.”

And they’re right, in a sense. It won’t hurt you to preheat chrome-moly. But it will take up more time. And the proven truth is that you don’t always have to preheat. If your material is less than an 1/8th of an inch (.125”) thick, preheating is not required.

If you’re interested in welding high-strength materials, here’s a couple of our favorite machines to use with chrome-moly: