The stress should be enough to give a silverback gorilla an aneurysm. You’ve got a $3,000,000 precision machine at the mercy of your torch. Every bead counts, every arc needs to be perfect. Engines roar in the distance as cars take their practice laps to the tune of 700 horsepower. But you don’t even hear the noise, because all your focus is somewhere between your filler material and the spark of your torch.

That’s a split-second of what it’s like to weld at the Indy 500. We literally don’t have a word yet to describe the pressure these welders should feel. And yet, if you take a quick stroll around the garage, you’ll notice the atmosphere is quite relaxed. For being the world’s biggest single day event, everyone’s acting like it’s just another day on the job. Who are these unshakeable welders and what role do their skills play at the Indianapolis 500?

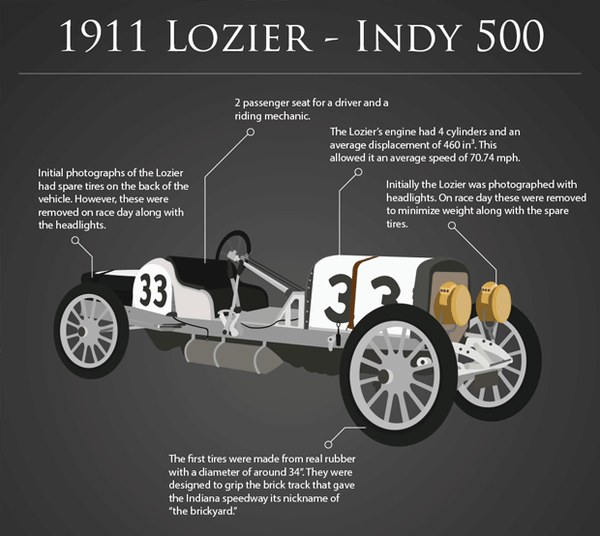

To understand that, we’ve got to go all the way back to the beginning. Back to 1911, where man was first starting to push the speed boundaries they’d been limited to for thousands of years. The first Indy 500 was established and 40 of the time’s most impressive racing machines were entered to compete. The cars were operated by a team of 2 people: a driver and a mechanic. While the mechanic would check the vehicle’s oil pressure, his most important job was watching behind the car to let the driver know when traffic was coming. On race day, every car pulled up to the starting line with their crew of two, except for one. Ray Harroun had replaced his riding mechanic with a single reflective mirror strapped to his vehicle.

The implications of the innovation were immediate. Ray Harroun and his Marmon Model 32-based Wasp racer took home the trophy. And yet the argument was made that Ray Harroun wasn’t the best driver at all, he simply hadn’t had to deal with the weight of an extra rider. Surprisingly, the next year’s race mandated that cars must include riding mechanics. The Indy 500 was about innovation, that’s true. But its founders didn’t want the sport to become an out-of-control arms race where everything rested on lighter, faster cars while the driver’s skill became nothing but an afterthought. Instead, they chose to focus on the crucial connection between man and machine, each playing an equally vital role to win the race.

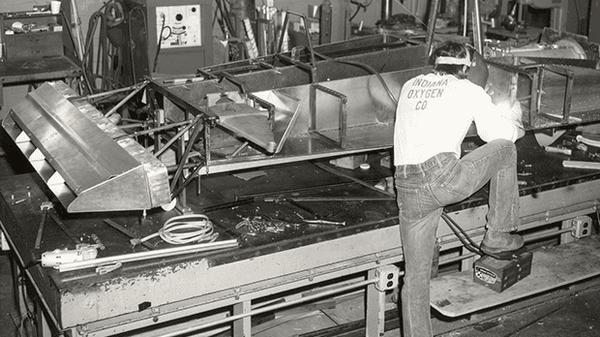

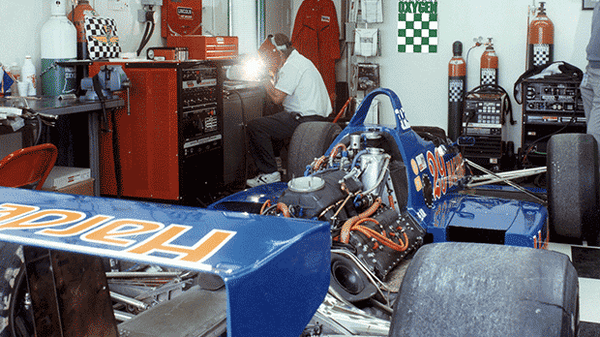

This philosophy has shaped every aspect of the sport, even welding. Crews are constantly looking for ways to innovate and welding is often a preferred tool to make these revolutionary ideas into a reality. But welding is also regulated. In fact, crews aren’t allowed to weld in their own garages at the Speedway. Instead, they have 2 options if they want something done. The larger teams might have a small, mobile booth in their fleet of trailers. However, most teams prefer the second option. It’s something here at IOC that we’ve prided our company on for the last 101 years. The Indiana Oxygen garage is the only facility at the tracks where welding is allowed indoors. Every year we’ve invited our friends from Lincoln Electric to help us work on everything from $200,000 racing chassis to repairing a pair of very important sunglasses.

While the types of welding jobs might vary, the quality can’t. Thus far, no racing accidents have ever been attributed to a faulty weld (knock on wood). So here we return to the question: What type of welding professional has the skill and mental fortitude to handle this type of pressure? Someone who’s used to working on experimental airplanes is a good start. Take, for example, Wyatt Swaim (famously known as Mr. Tig). He’s got over 30 years of experience working on high speed vehicles (both flying and nonflying) from the United States to Brazil.

Being a welder at the Indy 500 also requires a thorough knowledge of different metals. IndyCar parts are made of everything from 41xx steel (chrome-moly) to Titanium. While TIG tends to be the preferred method of choice for many welders based on its versatility, it doesn’t hurt to be skilled in the other major processes. Beyond that, welding at the Indy 500 also requires that you’re very familiar with everything from purging to plasma cutting.

In essence, the amount of skill and experience it takes to weld at the Indy 500 is what prepares these professionals to handle the stress. They’re used to working jobs where lives and millions of dollars are on the line. If anything, welding at the Indy 500 is something they truly enjoy. Few experiences can top working on the exhaust pipe of some famous racecar as a blur of metal, carbon, and rubber flies by you at 240 mph.

As for equipment, these professionals surprisingly aren’t using custom equipment made by NASA in a secret lab. Instead, they stick with the brands they trust, the same ones you’re familiar with. And that’s why we only supply equipment from companies we know you can rely on. Find welding equipment at the best price from the top brands here.