For decades, oxy acetylene was the golden method for cutting metal. Even Movies and TV shows usually portray metal cutting with a big ol’ flame coming out of the end of an oxy acetylene torch. Then plasma cutters were invented. For the most part, the early models designed for personal use had their flaws. But within a few years, even hobby welders could buy a solid plasma machine capable of producing some incredibly clean cuts. Today, both plasma and oxy acetylene are reliable, commonly-used processes. But there are definitely well-defined pros and cons for each method that make them unique from one another.

To be clear, we don’t have a dog in this fight. We sell both oxy acetylene and plasma equipment from the biggest, most trusted brands in the industry. We simply want to arm you with the knowledge to make the right decision for you.

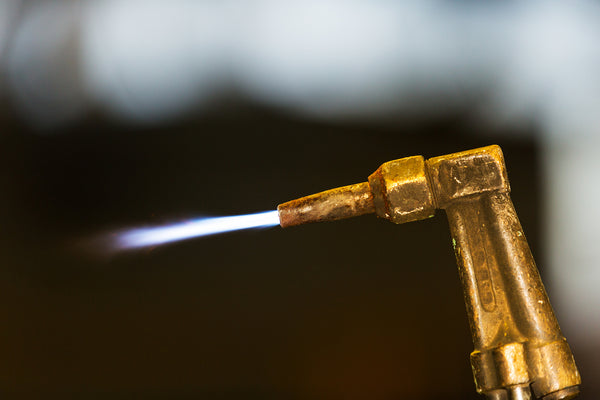

Why Oxy Acetylene?

You’ll find communities of welders that live and die by oxy acetylene. However, this isn’t so much the case with automobiles. Oxy Acetylene is a bulldozer. It cuts through thicker material faster than plasma while leaving a wake of destruction in its path. This means oxy acetylene needs more clean up compared to plasma (or even just cutting with a grinder). Because of this, oxy acetylene works best for brute force projects like rough cutting frames, preheating material or ripping pieces off an old junker. Don’t get us wrong, plenty of roll cages have been made with an oxy acetylene cutter. But the cleanup needed to make those cuts workable is by no means efficient.

Welders like to make the argument it’s easier to use oxy acetylene compared to plasma. Most experts would disagree, saying this is only the case because oxy acetylene has been around longer and more welders are familiar with it. Oxy Acetylene also doesn’t require electricity, but it does require gas cylinders. This means the initial price tag is lower but the upkeep cost can be more than plasma. A large part of automobile work can be done with oxy acetylene, just make sure you’ve got a good-quality grinder to help clean up your cuts and use on smaller pieces.

Why Plasma?

While being a newer cutting method to the industry, plasma offers the benefit of precision. Because automobiles use thinner material, you won’t usually run into a thickness that a plasma machine can’t get through.

A plasma machine won’t totally replace your grinder. While a plasma cutter leaves a pretty clean edge, you’ll still need to do a few things like removing any dross. But compared to doing all your cuts with a grinder, a plasma cutter is much more precise, efficient, and offers a lot of flexibility when you’re cutting. Essentially, a plasma machine can cut just about any shape you can think of while a grinder has a very difficult time with curves or small cuts.

This makes plasma machines ideal for almost any type of cut you’d do on an automobile. For most welders, the question comes down to how much versatility they need with their cuts. If all your cuts are straight lines through thinner material, a plasma cutter is ideal but not essential. But if you’re doing anything more complicated then rectangles and squares, a grinder simply won’t cut it (literally).

Plasma has a higher initial cost than oxy acetylene. But plasma machines also use compressed air rather than gas so you’re not having to refill cylinders. While there’s some that argue plasma is more difficult to learn, most experts point out that doing oxy acetylene the right way can be very complicated. In oxy acetylene, getting your flame to the right profile is more of an art than a science, while plasma is all about using the right settings, pulling the trigger and cutting straight.

All things being said, a crappy plasma machine will make your life into a living nightmare. That’s why we only sell plasma machines from the most trusted brands in the business including Hypertherm, Thermal Dynamics, Lincoln, Miller and a few other reliable names.

So, which process is right for you? That all depends on your situation. You might be fine with Oxy Acetylene and a grinder. Or, you might be looking at some more complicated cuts requiring the precision of a plasma machine. For more information on this equipment, check out the related products below.